Technology has a big role in our current world to make things easier and more efficient. Pharma manufacturing: Massive advances in technology A sector that technology has significantly affected is pharmaceutical manufacturing. By tapping automation technology, companies like Intelligence Technology can help make the way medicines are produced better: cheaper, safer, faster and more precise.

One of the major advantages of Life Science Automation automating processes in pharmaceutical production is that it will save a company a large amount of time and certainly money. And by having machines do things that were once done by hand, companies can now make medicines much more quickly and with many fewer mistakes. This means medicines can reach people who need them more quickly, potentially saving lives.

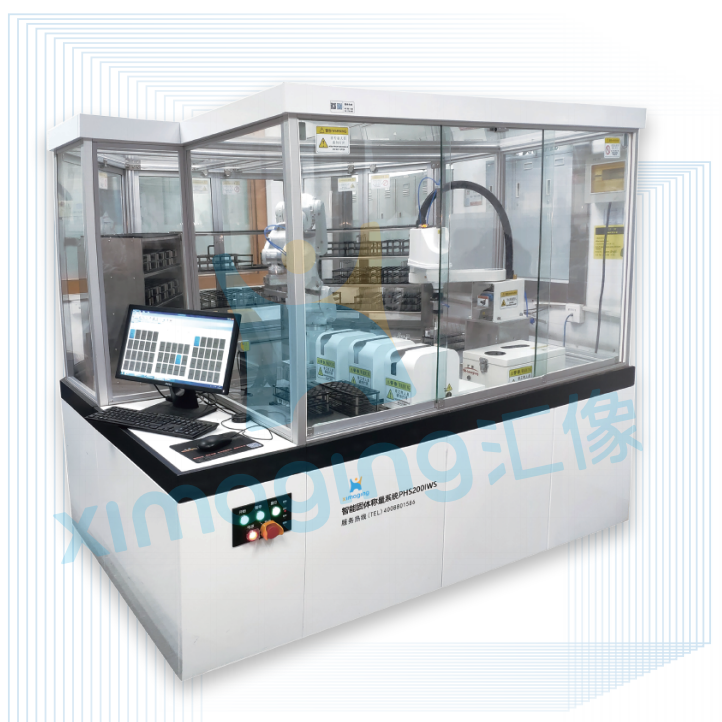

The pharmaceutical industry is being reshaped by automation technology. Machines can now perform tasks previously done by people mixing compounds, filling bottles and packaging medicines. Not only is this much faster, it also greatly mitigates the opportunity for errors. The High throughput cell imager technology automates a process that has largely remained the same for centuries, making how medicines are produced faster and more reliable.

Ensuring that drugs are made properly and are safe to use is one of the most important tasks in pharmaceutical manufacturing. Automation technology has a lot to do with this, as it allows companies to keep a close lid on quality control. Machines can measure materials more precisely than humans, That means that High throughput enzyme activity detector medications are less likely to be prepared incorrectly. This helps to assure that drugs are safe and effective for people who need them.

In the pharmaceutical industry, safety is paramount and automation is enabling businesses to raise their standards. Machines can accomplish dangerous work that it used to take humans to do, eliminating the potential for accidents. Automation technology also enables companies to track and monitor the production process more deliberately so any issues that do arise can be addressed and corrected immediately. A loss of control that Multi-functional liquid handler automation allows Companies can help ensure drugs made are safe and in a controlled environment by using automation techniques.

Drug companies like mine operate in a heavily regulated environment full of strict rules and standards that determine our interactions. Technology that automates is a huge way companies can be compliant. Machines are more accurate at recording data than humans, so companies can obtain clearer insight into their production processes. This Automated can be helpful to companies that want to prove that they are following all the rules and guidelines and avoid getting into trouble with regulators.